Chapter 13: Industries and Services

13.6 Manufacturing in a Globalized World

13.6.1 The Rise of Transnational Cooperations

Since the 1980s the U.S. and other developed countries have undergone de-industrialization, where the importance of the manufacturing industry in the labor market and the economy has been in decline. This decline is caused by three main factors:

- Automation: formerly manual tasks are done by software and robots.

- Relocation: factories moving to less developed countries to take advantage of lower wages and lax environmental regulations.

- Decrease in demand: certain items that used to be made by developed countries are no longer in demand.

Today, we see the rise of many companies around the world operate as transnational corporations (TNCs), companies that that owns and control the production of goods or services in at least one country other than its home country, with the ability to control production and sales in different countries. Some of the reasons that TNCs have provided for operating across different countries include: reducing labor costs, moving closer to the markets where the final products will be sold to reduce shipping costs, creating manufacturing jobs, and reducing poverty in developing countries.

Choosing the optimal location for a factory involves balancing interconnected costs such as:

- Capital: cost of rent, facilities, and machines

- Material: cost of fuel and raw materials

- Labor: cost of workers

- Market: distance to market and transportation costs

Relocating the factory to lower one cost, such as capital expenses or rent, could result in an increase in another related cost, like market accessibility or transportation expenses for delivering finished goods to customers. The primary objective is to identify a location that strikes a balance among these factors to achieve the lowest production costs possible.

Source: “Kobe Steel, Ltd-神戸製鋼所加古川製鉄所 1172657” by 松岡明芳 via Wikimedia Commons is licensed under CC BY-SA 3.0.

The location of some industrial activities such as those in the primary industry, which involves the extraction and production of raw materials through activities like farming, logging, fishing, or mining, are determined by site. The site refers to the physical/natural characteristic of a location. For example, a coffee plantation must be located on a site with farmable land. As another example, a logging company needs to be located on a site with trees to cut down. A steel mini-mill will have to be located near water which is necessary for cooling the blasting elements.

The location of other industrial activities such as those in the secondary industry, which takes raw materials and manufactures them into finished products (e.g. fish cannery, car factory, textile mill), are more dependent on their situation. Situation describes a location based on its relations to surrounding natural or man-made features. For example, a car factory may be situated just south of the U.S. border in Mexico, in order to take advantage of the lower labor cost in them maquiladoras in Mexico without incurring significant expenses to send the finished goods back to stores in the U.S. market.

While the economies of many lower income countries are dominated by primary and secondary industries, the economies of most developed countries are dominated by tertiary industries. Activities in the tertiary industry focus on providing services, including public services provided by the government (e.g. public utilities, schools), business services provided to other businesses (e.g. shipping, business loans), and consumer services provided to ordinary citizens (e.g. supermarkets, movie theaters).

13.6.2 Production Cost

Most companies aim to minimize production costs to maximize profits. Below, we’ll examine some of the factors influencing production costs:

Location Factors: Land, Material, and Energy: Factories may be situated in suburban or rural areas to benefit from lower rent where open land is abundant. Raw materials required for manufacturing are sourced globally to minimize costs, factoring in transportation expenses. Energy-intensive industries, such as steel production, are attracted to regions with inexpensive energy sources, like China.

Source: Bureau of Labor Statistics, U.S. Department of Labor, The Economics Daily, Manufacturing compensation costs in foreign countries and in the United States, 2011 at https://www.bls.gov/opub/ted/2012/ted_20121221.htm (visited August 12, 2024).

Labor Costs: The cost of labor varies significantly across countries (compare Figure 13.6.2), influencing where companies choose to locate their operations. Since workers are often unhappy with wage cuts, companies wishing to decrease labor costs may send jobs to countries where people are willing to work for less, or (if possible) replace workers with machines (i.e. automation) altogether. However, the savings in labor costs may be outweighed by the cost to transport the finished products to the market, so companies must balance their labor savings with potentially higher shipping costs.

Transportation: As discussed in an earlier chapter the economist Alfred Weber stated that transportation costs play a crucial role in determining industry location. Industries using ubiquitous raw materials, readily available in many places (e.g., water for breweries), prioritize proximity to markets to reduce transportation costs. Conversely, industries reliant on local raw materials (e.g., timber from forests) locate near extraction sites to minimize transportation costs, especially for bulk-reducing goods. Conversely, industries producing bulk-gaining goods (e.g., furniture from logs) locate closer to markets to reduce shipping expenses.

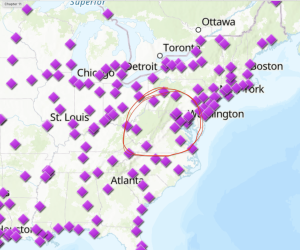

Foreign Trade Zones: Countries and states may be able to artificially make themselves more attractive to industries by offering tax breaks and other financial incentives, such as tariff (i.e. a tax or custom one pays when importing or exporting something) forgiveness, construction allowance, cash, and free healthcare for employees. An example is the United States, which established a number of Foreign Trade Zones (FTZs) in the country. These FTZs allow companies to import raw materials and parts (e.g. car parts) to their factories in the FTZs without paying tariffs that are normally due, assemble finished products (e.g. cars) in the FTZs from the raw materials and parts, and export the finished products from the FTZs to markets outside of the U.S. (e.g. car dealerships in Canada or elsewhere) without paying any tariffs.

Source: A screenshot of the ArcGIS Foreign Trade Zones in US map.

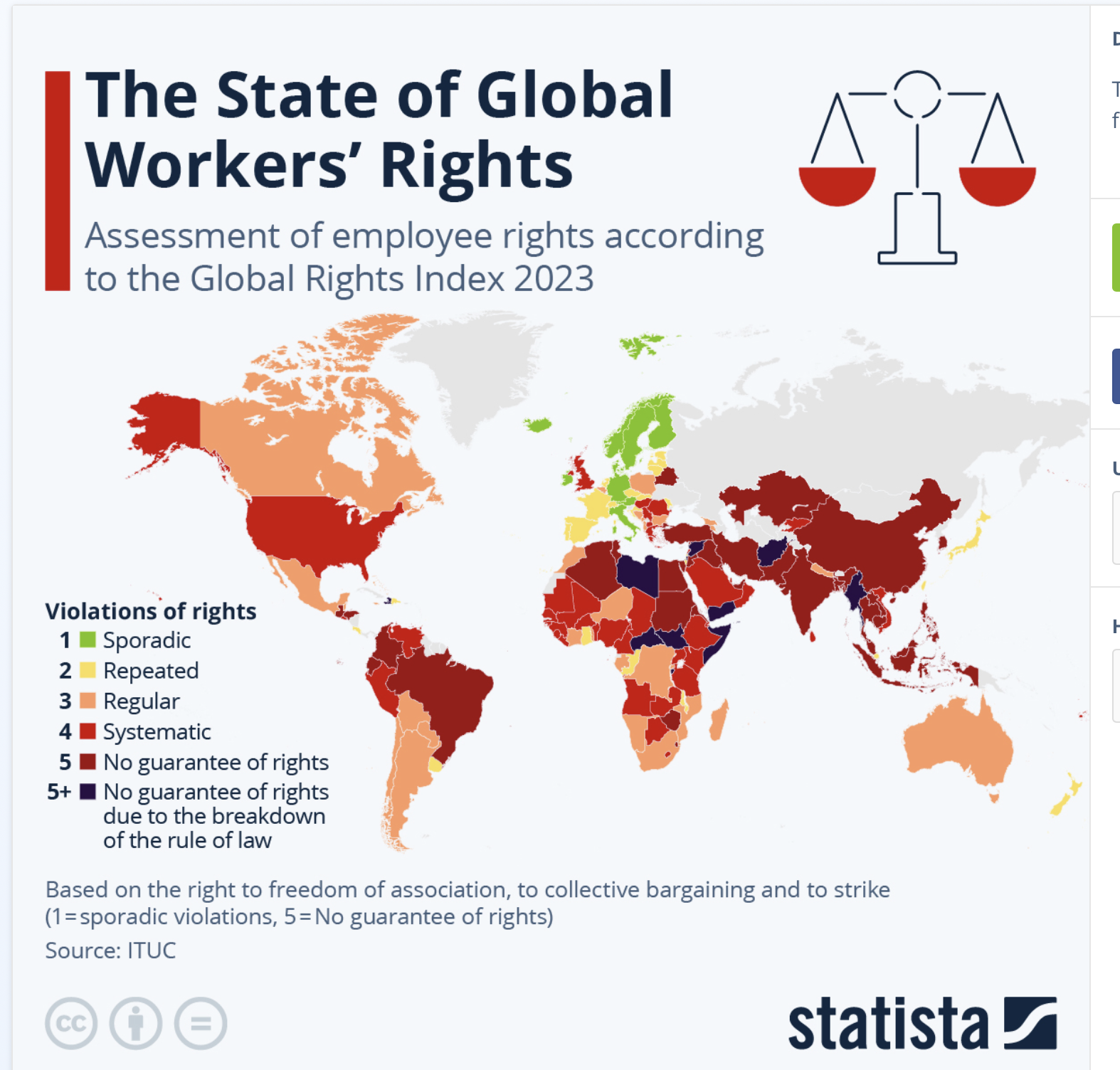

Industries may also be tempted to introduce new technology, build factories, and train workers (all examples of foreign direct investment) in countries with lax environmental or labor regulations, since they may be able to reduce the cost of production. However, some of those same countries may also have high levels of corruption and political instability or inadequate infrastructure (e.g. power lines, roads), which may drive industries away due to the risk to their investments.

Source: “The State of Global Workers’ Rights” by Anna Fleck via Statista is licensed under CC BY-ND.

The tendency of the rate of profit to fall (TRPF) is a theory of political economy, according to which the rate of profit—the ratio of the profit to the amount of invested capital—decreases over time. Thus the original inventor of a new product, such as the iPhone smartphones introduced in 2007, initially enjoys exclusive market access and significant profit margins. However, as competitors enter the market with similar products at lower prices as for example the Android phone introduced in 2008, a competitive race ensues between the original inventor and its rivals to reduce production costs and maintain profitability. This competition often involves strategies like automation, where machines replace workers, reducing labor costs. Companies may also cut wages for existing workers or relocate factories to countries with lower wages or tariffs, such as moving production from the U.S. to China or Vietnam. These measures are aimed at sustaining competitiveness and maximizing profits in a competitive market environment.

As some factories leave wealthier developed countries for developing countries to cut production costs, the economies of many developed countries shifted from the secondary industry to the tertiary/service industry that was already discussed above. However, a relatively new type of service job has been called the gig economy, where most gig workers (e.g. Instacart shoppers, and Uber drivers) work on their own schedules, at their desired locations, and often without employer-paid benefits.

Source: “Instacart carrot” by 292Jacob via Wikimedia Commons is licensed under CC BY-SA 3.0.

The Instacart logo is a simplified carrot. Logo since 2022.

The Pew Research Center surveyed U.S. adults in August 2021 and found that 16% of Americans have ever earned money through an online gig platform in at least one of the following ways:

- driving for a ride-hailing app;

- shopping for or delivering groceries or household items;

- performing household tasks like cleaning someone’s home or assembling furniture, or running errands like picking up dry cleaning;

- making deliveries from a restaurant or store for a delivery app;

- using a personal vehicle to deliver packages to others via a mobile app or website such as Amazon Flex; or doing something else along these lines

A brief assessment of recent trends

Reflecting on the trends discussed above and deciding who may be the “winners” or “losers”, some questions to consider are:

- Automation: Can everyone whose jobs were replaced by machines and robots learn new skills in time to start a new career? If not, what happens to those displaced workers?

- Factories: How may factories that moved to developing countries impact the long-term welfare of the people and environment of those countries?

- Gig Economy: Is the gig economy eroding laws that have historically protected workers against unsafe work conditions (e.g. pressured to work long hours or lower wages)?