Chapter 13: Industries and Services

13.3 The Industrial Landscape

Source: “Herbert E. French in Detroiter” by National Photo Company via Wikimedia Commons is in the public domain.

Have you ever wondered why Detroit became the “Motor City,” known for automobile manufacturing in the United States? Why Pittsburg is known for steel production, and why Hollywood became the entertainment capital of the world? In the early years of the twentieth century, when cars were assembled by hand, and when many of their components were made of wood, automobile manufacturers were located in many different places. One brand of car was made in San Francisco, another was made in Massachusetts, and yet another was made in Indiana.

By the end of World War I, Detroit was becoming the center of automobile production in America. In the early days of silent films, Flagstaff, Arizona was the site for the production of several movies, because many of the early films were about life in the West. Within a few years, however, the film industry had abandoned Flagstaff in favor of the Los Angeles Basin of California. In colonial times, the steel production center of North America was in Massachusetts. During the last half of the 19th century, Pittsburg, Pennsylvania replaced Massachusetts as the steel center of America. Why did these changes take place? Of course, there are many variables that determine whether an industry will prosper, however, location is one of the most important. Over the years, geographers have focused on several basic industrial location theories to explain why businesses and industries are located in particular locations and predict which locations help a business succeed. Von Thünen made the first efforts to identify the factors that account for the locations of industries.

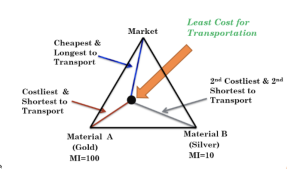

Von Thuenen’s ideas gave rise to the subsequent work of German geographers such as William Lanyard and Alfred Weber who were instrumental in the development of Least Cost Theory. Alfred Weber’s first major work on industrial location theory was published in 1909 in where he predicted that industries would locate based on the places that would be the lowest cost to them. He took for granted that industries are naturally competitive and aim to minimize their costs and maximize their profits. Much like Von Thünen, Weber did not try to explain actual real-world locations, but instead concentrated on identifying those factors that influence all industrial-location patterns. According to Weber, three main factors influence industrial location: transport costs, labor costs and agglomeration economies.

- Transportation: the site chosen must entail the lowest possible cost of A) moving raw materials to the factory, and B) finished products to the market. This, according to Weber, is the most important.

- Labor: higher labor costs reduce profits, so a factory might do better farther from raw materials and markets if cheap labor is available (e.g. China – today)

- Agglomeration: when a large number of enterprises cluster (agglomerate) in the same area (e.g. city), they can provide assistance to each other through shared talents, services, and facilities (e.g. manufacturing plants need office furniture).

13.3.1 Transportation

1) Weber felt that transportation was the strongest factor in determining the location and that industries wanting to locate where transportation costs are minimized must consider two issues: the distance of transportation to the market and the weight of the goods being transported. Regardless of the method (ship, rail, truck, air), transportation cost is determined by the weight of the goods being shipped and the distance they are being shipped. The heavier the goods and the farther the distance, the more expensive it is to ship.

Source: “Figure 6.7 Weber Least Cost Theory Locational Triangle (reproduced by author from original image by Vikas Sutar)” is licensed under CC BY 4.0. Retrieved from Human Geography: An open book for Advanced Placement Created by the Puyallup School District.

In one scenario, the weight of the final product is less than the weight of the raw material going into making the product—the weight losing industry. For example, in the copper industry, it would be very expensive to haul raw materials to the market for processing, so manufacturing occurs near the raw materials. Besides mining, other primary activities (or extractive industries) are considered material oriented: timber mills, furniture manufacture, most agricultural activities, etc. Often located in rural areas, these businesses may employ most of the local population. As they leave, the locale area loses its economic base.

In the other, the final product is equally as heavy as the raw materials that require transport. Usually, this is a case of some ubiquitous raw material, such as water, being incorporated into the product. This is called the weight-gaining or bulk-gaining industry.

This type of industry tends to build up near a market or raw material source and is sometimes called foot-loose industry (Figure 13.3.2). In some industries, like heavy chemical industry, the weight of the raw material is less than the weight of finished product. These industries always grow up near a market.

13.3.2 Labor

Source: “Weber’s labor distortion adjustment for Least Cost Theory (reproduced by author from original image by www.lewishistoricalsociety.com)” is licensed under CC BY 4.0. Retrieved from Human Geography: An open book for Advanced Placement Created by the Puyallup School District.

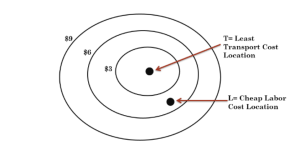

2) Because labor costs vary from place to place, and because these differing labor costs are the product of variances in wage rates and worker efficiencies, Weber thought of labor as a distortion of the basic transportation pattern that was driven by transportation costs (Figure 13.3.3. Accordingly, after finding the best location relative to transportation costs, he considered the ways in which labor costs influenced the location of factories and plants. To do this, he plotted the spatial variances of transportation costs to create a transport cost surface. He then contrasted regional labor costs with regional the pattern of transportation costs.

Weber noted that as transportation systems became more efficient, and hence less expensive to use, labor costs came to more heavily influence industrial locations. He also found that industries dominantly affected by labor costs tend to concentrate in a few places. Therefore, lower transportation costs tend to intensify the natural tendency of like industries to agglomerate in one location.

13.3.3 Agglomeration

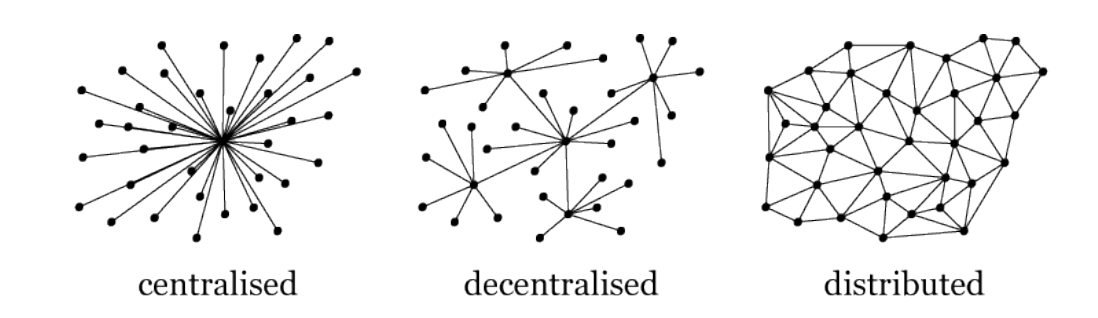

3) Weber also employed a classification system based on local and regional factors. Local factors included the influences of agglomeration and deglomeration. Similar businesses normally gain an advantage when the cluster or agglomerate (centralize) in a specific location. Deglomeration is the tendency of industries to decentralize or disperse from a given location when rent becomes too expensive and impacts profits (see Figure 13.3.4 below).

Source: “Visualizing agglomeration concepts (reproduced by author from original image by https://allgeographynow.wordpress.com/tag/agglomeration/)” is licensed under CC BY 4.0. Retrieved from Human Geography: An open book for Advanced Placement Created by the Puyallup School District.

Weber argued that there are two major ways in which firms benefit from agglomeration. In the first place, it could bring about the enlargement of a factory, thereby leading to greater economies of scale. Additionally, agglomeration allows similar industries to benefit from being near one another. This is because they can share specialized facilities, services, and equipment. In his analyses, Weber considered only “pure” or “technical” agglomeration. He did not examine the impacts of “accidental” agglomeration (concentrations that occur for other than reasons associated with spatial economics).

In Weber’s basic industrial location model, there is only one specific market location and one of the assumptions of this model is that all transactions take place on this site. Moreover, Weber assumed that there would be no limit to the quantity of the product that would be purchased at the specified price (in other words, in Weber’s model, the price of a good did not affect demand) which served to simplify the model.

Source: “Global Staff Shortages Balloon in Just Six Years” by Katharina Buchholz via Statista is licensed under CC BY-ND 4.0.

Other scholars, however, were convinced that, in making this assumption, Weber greatly limited the accuracy of his model. After all, demand is not confined to one single site but is instead scattered unevenly throughout a region. Moreover, it is seldom true that buyers are confined to only one retail merchant. Instead, they normally have a number of choices and, if all else is equal, they will choose the closest establishment from which to make a purchase. Even so, better prices and services may offset the costs of distance. This is in keeping with the common advertisement slogan of automobile dealers located outside the boundaries of a city, “drive a little, save a lot!”

During the last years of the 20th century, developments in transportation diminished the relevance of Weber’s theory. First, freight rates have increased at a faster rate than the costs of raw materials, but relative transportation costs are declining. This means that the impacts of transportation costs on industrial location and market analysis are relatively less important than they were at the beginning of the 20th century when Weber first articulated his theory. And second, natural resources are now less important because smaller, lighter and smarter products have replaced the heavier products of the past. In particular, plastics and lighter materials made from soybeans, petroleum, and other fibers have replaced the use of steel and wood. As a result, furniture and appliances are lighter (and sometimes stronger). Even automobiles now use a great deal of plastic and other fibrous materials as a substitute for steel. It is far less costly to move petroleum through pipelines, or to ship plastics than it is to ship wood, iron ore, and steel.

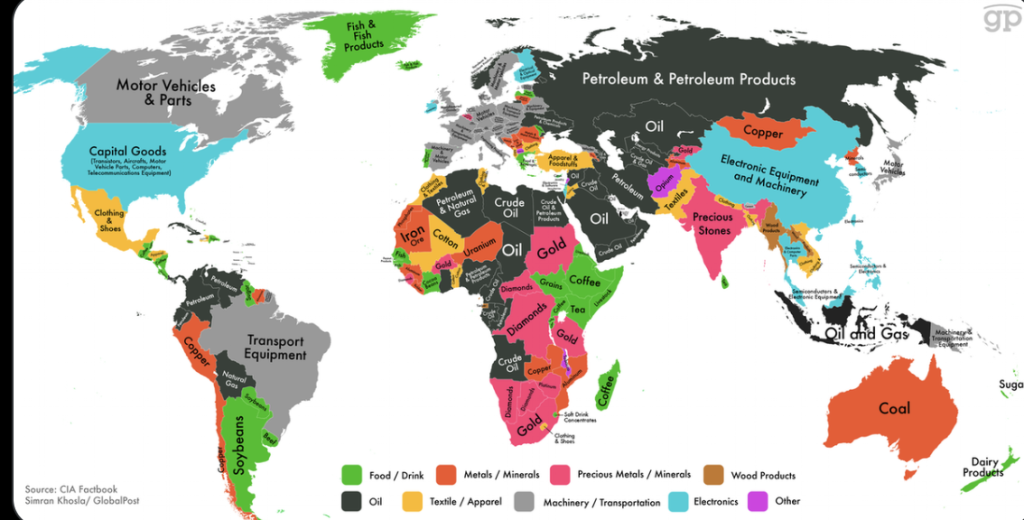

Currently, labor tends to be the most important determinant of industrial location. This is particularly true for firms that produce expensive, high-tech goods. For most of these firms, transportation costs are of minor importance. In part, this is because high-tech goods are usually relatively light and small. This is nothing new, however. Long ago, the Swiss figured out that as a land-locked mountainous nation, they could not competitively ship their dairy products to foreign markets. Therefore, they processed liquid milk into far less bulky cheese and chocolate. They also realized that anything they manufactured should have a high value relative to its bulk and weight. Thus, instead of making automobiles or steam trains, they made timepieces.

Source: by Simran Kholsa via CIA Factbook is licensed under CC BY.

Even the Dutch, with access to excellent ports and water transportation, realized the benefits of shipping high-value, low-bulk products. Thus, they processed diamonds and focused on flower bulbs, cheese, and chocolate. In recent years, firms have developed many new and innovative ways in which to avoid transportation costs. For example, soft drink manufacturers do not ship full bottles of their products all over the world. Instead, they ship containers of syrup to local bottling plants where water is added to the syrup.